For warehouse cooling, High-Volume, Low-Speed (HVLS) fans have become increasingly popular in recent years. These large industrial fans move a lot of air at a low speed, creating a gentle breeze that can cool people and equipment more effectively and energy-efficiently than traditional high-speed fans or air conditioning.

However, designing an HVLS fan system is not a one-size-fits-all proposition. There are several factors to consider, from the size and shape of the space, to electrical and fire alarm requirements, to the type of products stored and the specific needs of the workers. In this blog, we’ll explore five key factors to keep in mind when designing an HVLS fan system for your warehouse or industrial facility. If you’re looking to improve comfort, productivity, and energy savings, read on to discover how to get the most out of your HVLS fans.

The first step in designing an HVLS fan system is to determine the maximum size of the ceiling fan, which depends on the height at which it will be mounted. Generally, the higher the fan, the larger it needs to be to effectively move air throughout the space.

This is similar to the way a helicopter achieves true lift: when the diameter of its blades equals the distance between the rotor and the ground. See Figure 1 below.

Figure 1 – In this figure, you will see a helicopter taking off from the ground. This figure demonstrates when a helicopter achieves true lift. When the helicopter is a full blade diameter off the ground, that is when it will achieve true lift. We relate this figure to how we determine the maximum size of the HVLS fan.

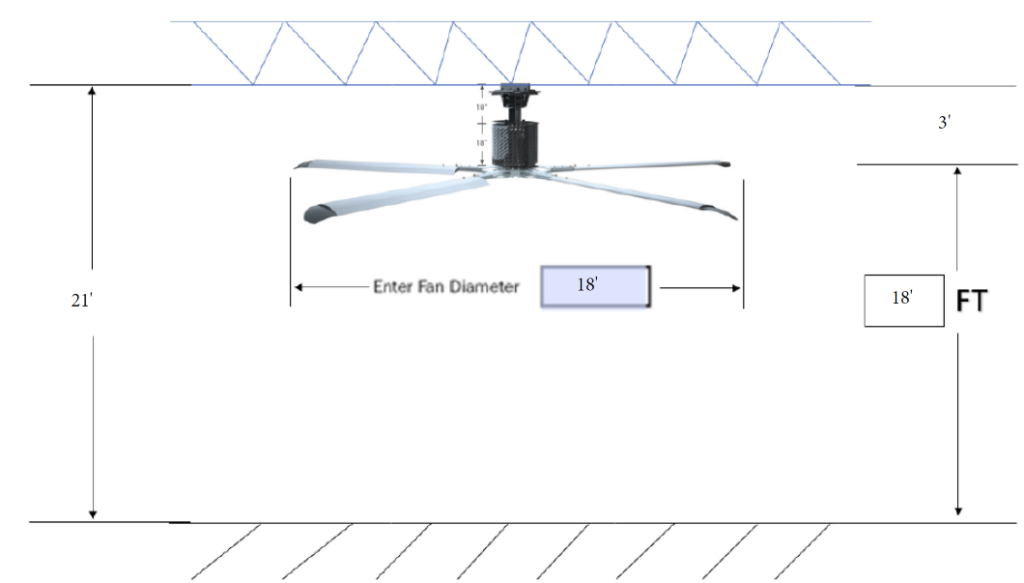

In the case of an HVLS fan, we want the diameter of the fan and the fan’s height above the finished floor (AFF) to be equal. It is generally standard for industrial HVLS fans to come down 36.” If we need to drop the fan down any further, we can add extension tubes. Figure 2 demonstrates how we determine the maximum HVLS fan diameter.

Figure 2 – In this figure, you will see how to determine the maximum diameter of an industrial HVLS fan being mounted to a bar joist system. Since the HVLS fan’s AFF is 18-feet, we determined that the maximum diameter of the fan is 18-feet.

Another factor to consider when determining the maximum size of an HVLS fan is the slope of the ceiling. Any ceiling slope or pitch can affect the dropdown length, which will affect the distance between the fan blades and the floor. This in turn can affect the size of the fan needed to achieve optimal air movement.

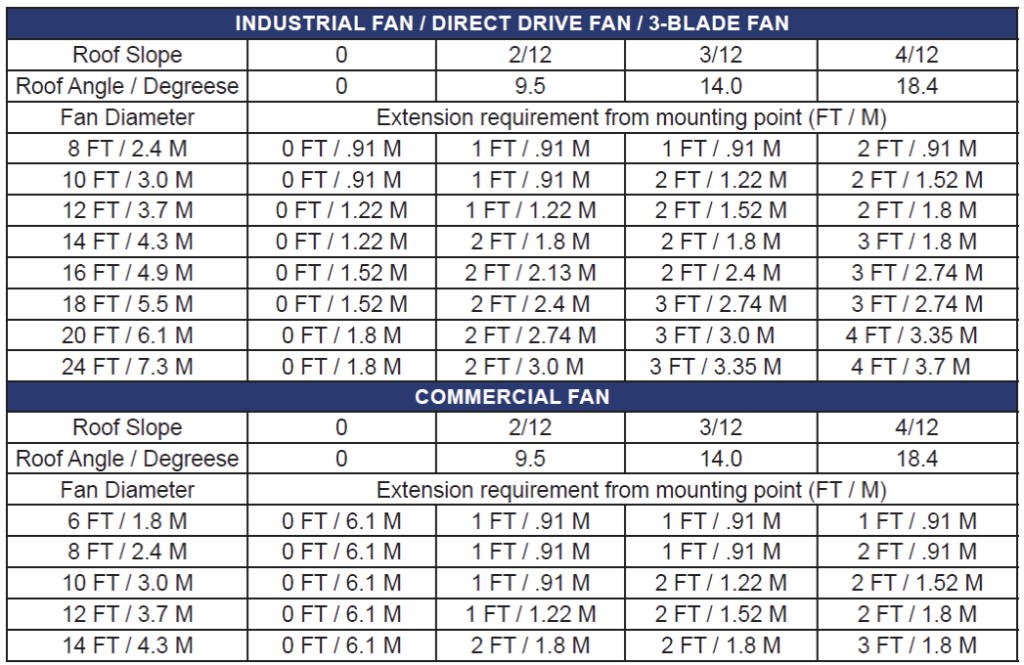

An extension tube can be added to accommodate a sloped ceiling, and its length depends on the pitch of the ceiling. Table 1 below shows the correlation between the pitch of the roof and the size of extension tube required:

Table 1 – This table was created by Epic Fans and can be found in the HVLS Application Guide. This table is an easy way to determine which size extension tube you need for both industrial and commercial HVLS fans based on the slope, or pitch, of the roof.

For example, if the ceiling has a pitch of 9.5 degrees and the mounting height is 20 feet, an industrial HVLS fan with a diameter of 16 feet (21 ft – 3 ft – 2 ft = 16 ft) would be appropriate.

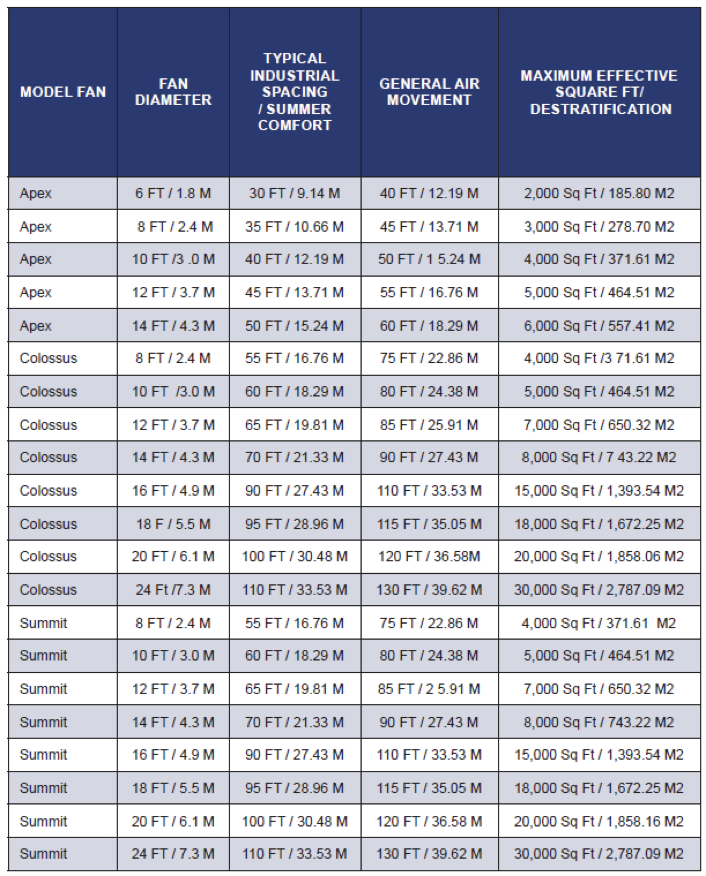

Now that we know the maximum size of your fan, we need to determine how many you need and their optimal. This is where the airflow diagram in Table 2 below helps with the HVLS fan system design.

Table 2 – This table was created by Epic Fans and can be found in the HVLS Application Guide. This table is an easy way to determine the size, spacing, and quantity of HVLS fans required.

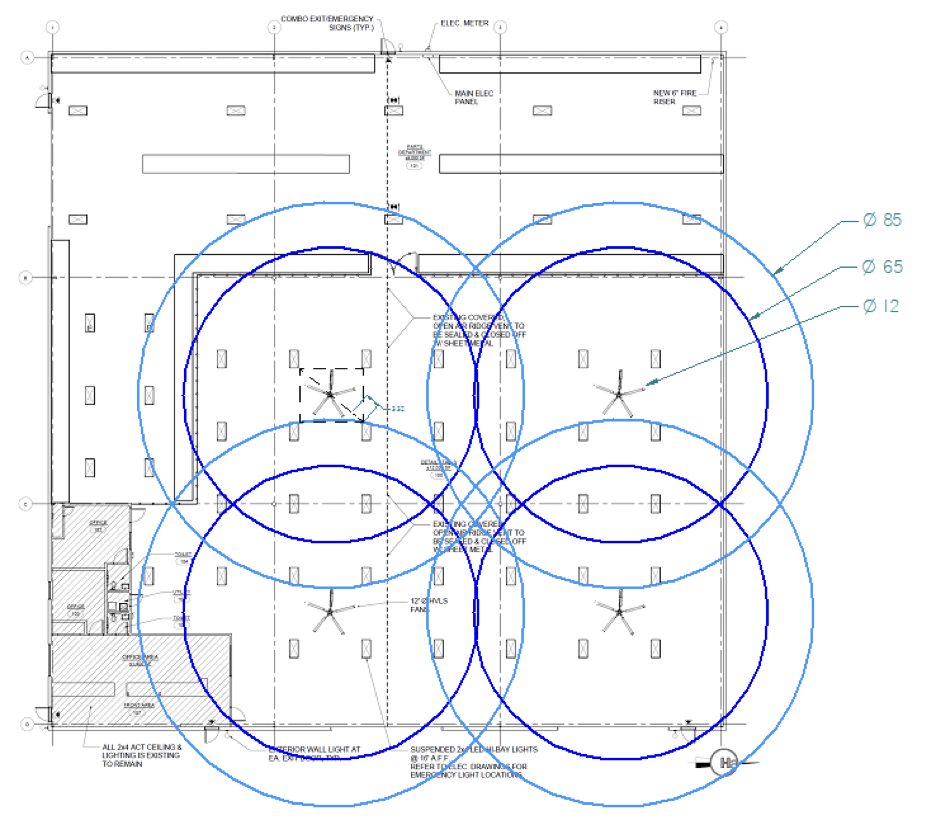

Figure 3 below shows our example space, where we see that a 12-foot HVLS fan has a general airflow diameter of 85 feet. This means that a single fan may not be enough to provide optimal airflow and destratification throughout the entire space. Based on this information, we might decide to install four 12-foot industrial HVLS fans to cover the entire space effectively. With four fans, we can achieve our desired airflow and keep a 2-foot required separation from the lighting, which will prevent strobing.

Figure 3 – This figure was created by the design team at ChopAir for a maintenance facility in Jacksonville, FL. The design team used Table 2 to choose the spacing between fans. Furthermore, the design team verified that the 12-foot fans were at least 2-feet from the LED lights to prevent strobing.

We also need to consider how fans will interact with other systems in the space, such as air diffusers and fire sprinklers.

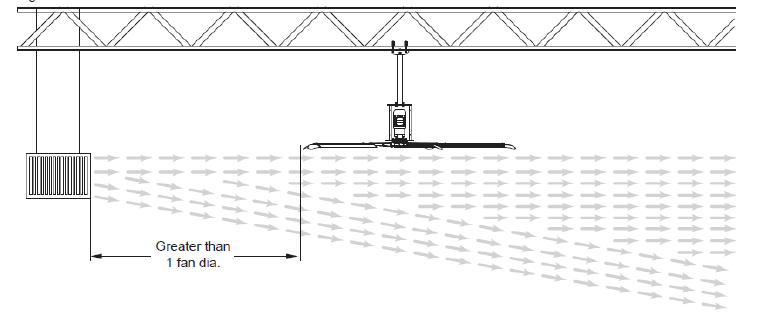

According to industry standards shown in Figure 4 below, if an HVLS fan is mounted above an air diffuser, it should be positioned at least one fan diameter away from the diffuser. This helps to ensure that the airflow from the fan doesn’t interfere with the distribution of air from the diffuser.

Figure 4 – This figure was created by Epic Fans and can be found in the HVLS Application Guide. This figure is an easy way to determine the HVLS fan spacing from a diffuser if it is mounted above the diffuser.

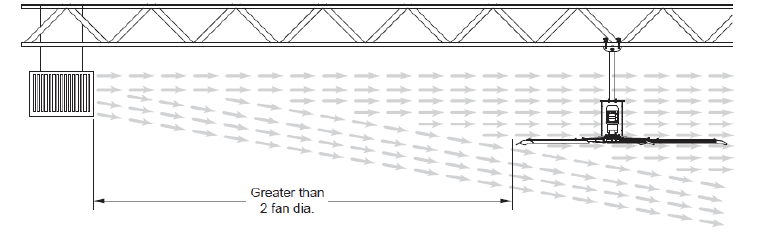

If the fan is mounted below an air diffuser, it should be positioned at least two fan diameters away from the diffuser. See Figure 5 below. This helps to ensure that the airflow from the fan doesn’t create turbulence or disrupt the air coming from the diffuser.

Figure 5 – This figure was created by Epic Fans and can be found in the HVLS Application Guide. This figure is an easy way to determine the HVLS fan spacing from a diffuser if it is mounted above the diffuser.

In addition, it’s important to ensure that HVLS fans are mounted at least three feet below fire sprinklers, in accordance with the NFPA 13 Standard. This helps to ensure that fans don’t interfere with the operation of sprinklers in case of a fire.

By considering these factors when designing your HVLS fan system, you can ensure that your fans are placed in the most effective safest positions possible. Consult with a professional engineer or HVLS fan expert to confirm that your system is properly designed and installed for maximum efficiency and safety.

Once you have determined the maximum size and placement of your HVLS fans, the next step is to consider your mounting support system. Depending on the type of ceiling support structure in your space, you may need to include additional mounting supports to ensure that your fans are securely installed and functioning optimally. Click here for a great video on the different types of installation supports.

If you are mounting your HVLS fan to an I-Beam, you may not need any additional support, since the standard mount clamps directly to an I-Beam. See Figure 6 below.

Figure 6 – This figure was created by Epic Fans and is a snip from the Mounting Options video.

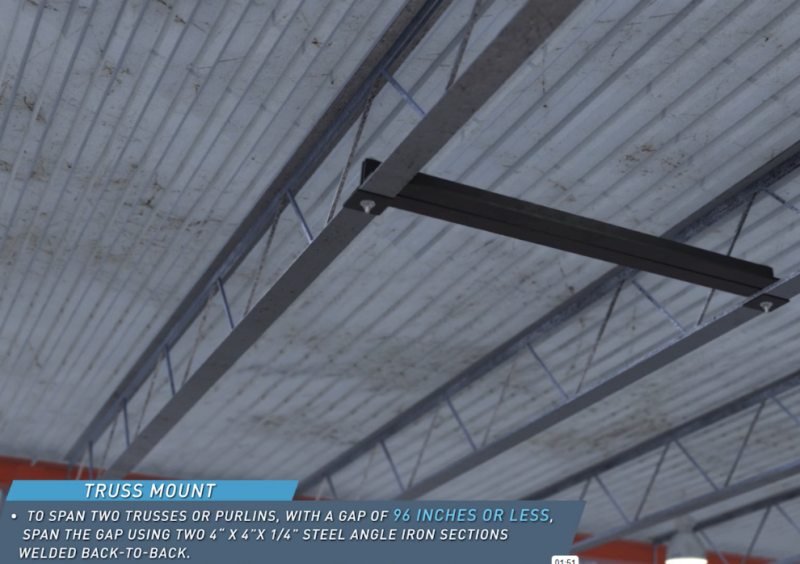

If you are mounting between bar joist trusses, you will need a truss kit per Figure 7 below. At ChopAir, we use a 3” x 3” truss kit instead of the 4” x 4” kit for a more streamlined installation process. This is an example of when we would use a Universal Truss Kit.

Figure 7 – This figure was created by Epic Fans and is a snip from the Mounting Options video.

If you are mounting your HVLS fan to a z-purlin or pre-engineered structure, you will need a Z-purlin Truss Kit per Figure 8 below. These kits are specifically designed to provide the additional support required by these structures.

Figure 8 – This figure was created by Epic Fans and is a snip from the Mounting Options video.

By selecting the appropriate mounting support for your HVLS fan system, you can ensure that your fans are securely installed and functioning optimally. Consult with a ChopAir representative if you need to verify the proper installation method.

Depending on the type of fan, there are several voltage options, typically including:

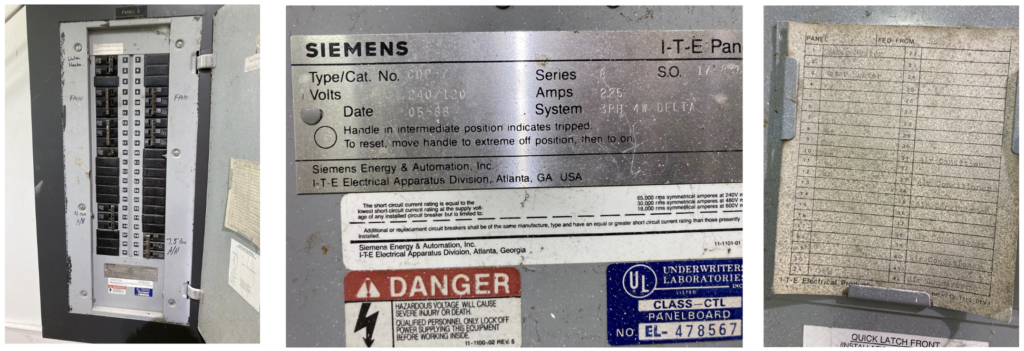

For an existing building, look for the tag and schedule in your electrical panel to determine the proper voltage. It is always best to consult with a licensed electrical contractor to determine if it is safe to install on a specific electrical panel. See an example of a picture of a tag and schedule below in Figure 9.

Figure 9 – in this figure there are three pictures that ChopAir representatives take of each electrical panel on site visits. In the left image, you can see the tag of the panel on top which reads “Panel D”. Also, you can see the used breakers that correspond to the panel schedule in the far right picture. In the middle picture, you can determine that the panel is 240 / 120 Volts.

To ensure that you have the adequate amount of space on your existing electrical panel, consult with the electrician who will be connecting power to your fan.

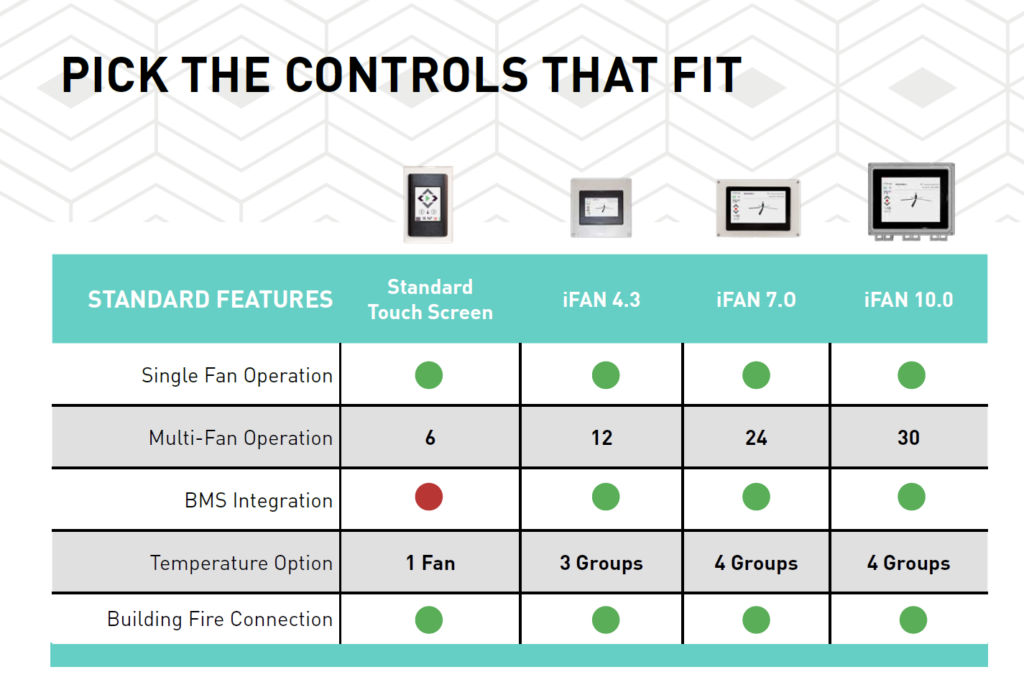

When selecting the right controller option for an HVLS fan system, it’s essential to consider your specific needs and requirements. The right controller can help optimize energy usage, improve comfort, and ensure easy usability. To help you make an informed decision, we’ll be discussing the different control options features in Table 3 and the fire alarm options in Figure 10.

Table 3 – in this table created by Epic Fans, there are four controller options for an HVLS fan: Standard Touch Screen, iFan 4.3, iFan 7.0, and iFan 10.0. Each controller has a specific amount of fan quantities and feature add-ons.

This is the default controller that comes with every fan. It can control up to six fans and allows you to adjust fan speed, direction, and on/off settings. However, it does not integrate with a Building Management System (BMS) and would require one temperature control sensor per fan.

The iFan series is an intelligent fan controller that can integrate with a BMS system, making it ideal for large facilities. It only requires one temperature and humidity control sensor per fan group, making installation easier and less expensive.

Figure 10 – in this figure there are two options for Building Fire Connections. For the Standard Touch Screen, the Standard Fire Panel is required. For the iFan Series, the Networked Fire Control Panel is required. Both panels require 120 V power.

If you want to daisy chain your fans together for a fire alarm system, you will need a Fire Control Panel series per Figure 7. If you are operating with the Standard Touch Screen remote, then you will need the Standard Fire Control Panel. If you are operating with the iFan series, then you will need the Networked Fire Control Panel.

It’s crucial to consider your specific needs when selecting the right controller for your HVLS fan system. For instance, if you’re looking to integrate your fan system into an existing BMS system, then the iFan Series would be the best option. On the other hand, if you’re looking to improve safety, you might want to consider the Fire Control Panel Series.

It’s also important to consult with a ChopAir representative to ensure you’re getting the right controls package for your facility. A representative can help you determine the best options based on your specific needs and provide guidance on installation and maintenance.

HVLS fans are an excellent solution for modernizing your building, providing cooling airflow while improving energy efficiency. They may look simple, but many factors are involved in optimizing a fan system. Thankfully, we know a thing or two about fans. Consult a ChopAir representative today to get started.

1519 W 16th St

Suite 100

Kansas City, MO 64102

4419 W Ballast Point Blvd

Tampa, FL 33611